CNC (computer numerical control) has changed the face of the manufacturing industry by automating the motion of factory tools and machinery using pre-programmed software. It has changed the process of how components are manufactured where all the three-dimensional cutting jobs can be done with the help of a single set of prompts. CNC routers and CNC milling machines are two of the more popular types of CNC machinery that manufacturers can consider for their workshop or manufacturing facility.

To assist your decision on that matter, this article compares the characteristics, applications, and suitability of CNC routers vs milling machines. This comparison will serve as your comprehensive guide to understand the nuances of each tool, whether you are a hobbyist seeking to optimize your workshop or a business owner aiming to strengthen production capabilities.

What is a CNC Router?

Generally, a CNC router is a computer-controlled cutting machine that is primarily used for softer applications. It acts like a normal hand held router, but with the added advantage of being able to computer control it, which minimizes the possibilities of cutting errors by small percentages. These machines are powerful tools that can slice, engrave, carve, and shape different materials with great efficiency and precision.

Key Features

Common characteristics of CNC routers are:

● High-RPM Spindles: CNC routers don't simply run higher RPMs than milling machines, they run much faster feed rates as well, meaning less time will be spent cutting. With a high-speed operation, they're well suited for softer materials.

● Gantry Style: Most CNC routers fall under the gantry-style design, where the cutting head moves over a stationary workpiece. Having two vertical columns on each side with the cutting tool spanning a horizontal frame, this design is perfect for working on large sheets of material.

● Multi-Dimensional Axis: CNC routers usually can move in 3 to 6 axes. Standard 3-axis machines can cut up and down (Z-axis) as well as in the X and Y direction, while more advanced 4-axis and 5-axis models can cut rotationally, coming in from other angles to create more intricate designs.

● Larger Work Area: In general, CNC routers have a larger cutting space, making them very convenient for working with sheet materials as well as for large format objects.

● Material Compatibility: CNC routers are typically designed for softer materials like wood, plastics, foam, composites, and softer metals such as aluminum and magnesium.

What is a CNC Milling Machine?

CNC milling machines are heavy-duty, computer-operated cutting tools for machining harder materials with high precision. Unlike routers, which prioritize cost and speed, milling machines are designed for strength and rigidity and can handle heavier cutting operations with impressive precision.

Key Features

Features of a CNC milling machine:

● Rigidity: CNC mills are built with a heavy-duty, permanent frame that allows them to perform highly vertical and horizontal cutting. This inflexible construction enables them to process more resilient materials while ensuring the utmost precision.

● Low-Speed High-Torque Spindle: A CNC mill uses a spinning spindle like a router except that it only spins between 1,000 to 20,000 RPM compared to a router. These industrialist titanium cuts give them the ability to make shallower cuts in harder things, but without sacrificing accuracy

● Multiple Axes: Basic CNC mills work on 3 axes while more advanced models can have up to 12 axes of movement. Such a wide range of motion allows complex machining that is impossible with simpler equipment.

● Precision: CNC mills are only the same CNC machines that can be designed with precision and dimensional accuracy in mind, making design projects with tight tolerances and intricate designs perfect for doing.

● Material Compatibility: CNC milling machines can cut harder materials, they are perfect for cutting metals (steel, titanium, stainless), plastics, and composites. They could offer the services to cut these materials at a high speed all without losing precision and accuracy.

Key Differences Between CNC Router and Milling Machine

Design and Structure

CNC routers are generally built in lightweight, gantry configurations, with the cutting head moving over a stationary workpiece. This involves two vertical columns on either side of the cutting tool, which moves along a horizontal framework. It is less rigid than a milling machine and thus has considerably lower precision capabilities, however is much faster and has a much larger area of operation.

CNC milling machines are designed with a robust, cast iron or steel framework that ensures exceptional rigidity and stability when in operation. They have a fixed frame and a movable workpiece for vertical and horizontal cutting.

Material Compatibility

CNC routers are made to cut softer materials. They shine at cutting wood, plastics, foam, composites, and soft metals — aluminum and magnesium. They can also work quickly, which is ideal for processing these materials without excessive heat or damage.

Due to this fact, CNC milling machines are designed to work with much hard and inflexible materials. They are able to process steel, stainless steel, titanium, copper, and other solid metals that would harm or damage a CNC router. Different sorts of metals like aluminum and steel are too hard for regular routers to do a good job because they will go deep while CNC routers won't.

Precision and Accuracy

The CNC router has a relatively good precision that is sufficient for many applications (it is usually not comparable to a milling machine). They have a less rigid construction and higher operating speeds that result in increased vibration and a propensity for deflection during cutting operations.

They offer much higher precision and accuracy compared to CNC milling, which makes them great for complex geometries and intricate designs. Their inflexible construction minimizes vibration and tool deflection, making for extremely precise cuts within tight tolerances. CNC mills use more advanced control systems that allow the cutters to move very precisely over rigid structures.

Speed and Torque

CNC routers run at much higher RPM than milling machines (18,000–24,000+ RPM). During high-speed operations, feed rates are high and material removal is rapid within soft material. However, the rotary cutters of CNC routers provide less torque, making them less effective for deep cuts in hard materials.

While CNC milling machines turn at slower RPM than routers, they offer much greater levels of torque. This enables them to make deeper, more aggressive cuts in harder materials without stalling or damaging the cutting tools. Because CNC mills operate at lower speeds with high torque, they are more efficient at removing large quantities of material from tough workpieces.

Cutting Area and Z-Axis Depth

Since CNC routers have a larger cutting area than milling machines, so they are mostly used to process large sheets of material. The expanded work envelope enables both the manufacture of larger components and the concurrent production of multiple, smaller parts. That said, a CNC router does tend to have a shallower Z-axis travel depth meaning that although routers are great at processing standard material width quickly, the overall thickness of material they can adequately process is thinner with shallower depths and usually less appropriate for cuts with depth.

The smaller cutting area of CNC milling machines especially when compared to routers limits the workpieces that they can accommodate. They replace this limitation with a much larger travel capability in the Z-axis. These CNC mills can work with thicker materials and make deeper cuts, which is crucial for many metalworking applications.

Cost and Maintenance

CNC routers are usually cheaper and easier to maintain, but they do have residual dust and swarf that need regular cleaning, especially when used for cutting wood.

CNC milling machines require a considerable initial investment owing to their rugged design, sophisticated technology, and accuracy. They also have much higher operational costs, associated with costlier tooling, higher power requirements, and more frequent maintenance. CNC mills require more maintenance since they work with tougher materials and at higher stress levels.

Applications and Use Cases

CNC Router Applications

CNC routers can be found in a number of industries and offer a versatile and efficient method for shaping softer materials. Some common use cases include:

● Woodworking: CNC routers perform exceptionally well in woodworking applications, such as producing drawer fronts, drawers, shelves, countertops, and cabinet doors.

● Sign Making: CNC routers are heavily utilized in the sign industry to cut signs out of different materials like plastic, foam, wood, bronze, and aluminum. With 3D capabilities, sign makers can create signs with dimension and texture.

● Modeling and Prototyping: Working in plastics, wood, foam and aluminum to build models and prototypes for product development.

● Music Instruments Sector: Production of musical instrument parts with a high level of repeatability and high precision resulting in customized musical instruments with distinct requirements.

● Exhibition & Display: Collaborating for custom tradeshow & exhibition works using acrylic, vinyl, glass, and wood.

CNC Milling Machine Applications

Industries that require precision machining of tougher materials to exact tolerances rely heavily on CNC milling machines. Their applications include:

● Aerospace: Fabricating aeronautical parts out of materials such as titanium and aluminum, where high precision and light-weighting durability is important.

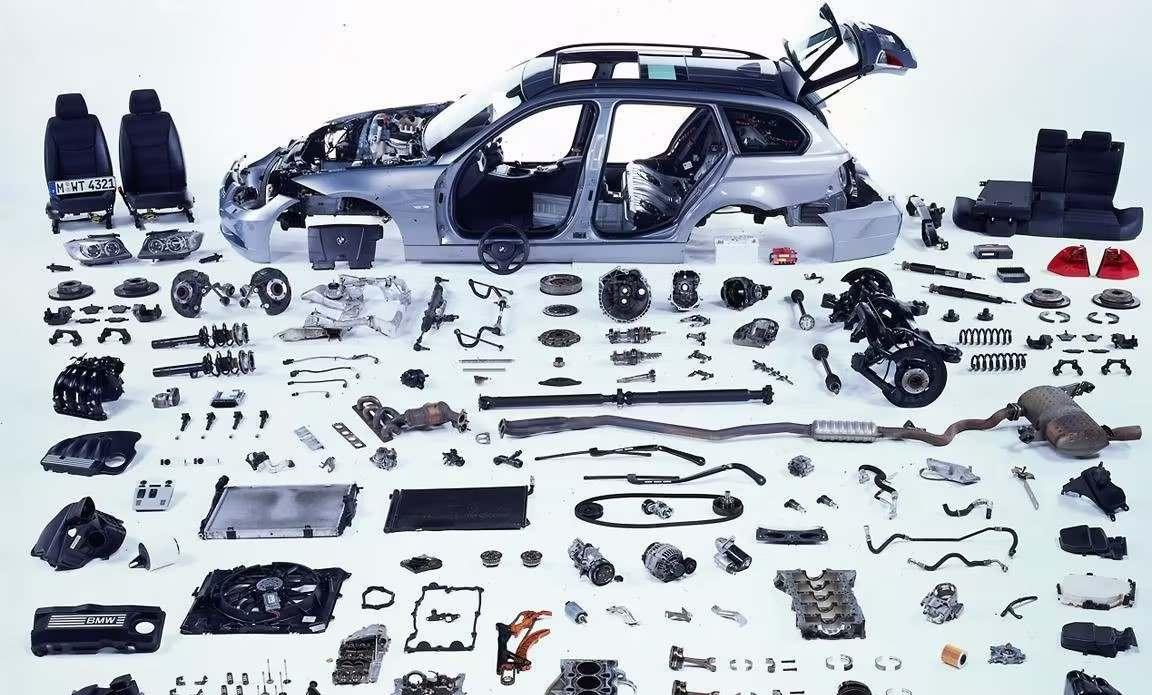

● Automotive: Parts such as cylinder heads, drive axles, suspension parts, exhaust parts, and gearboxes can all be made with the efficiency and precision the automotive industry requires.

● Medical Devices: Manufacturing precision parts for medical devices and implants where tight tolerances and biocompatible materials are essential.

● Electronics: Making precision housings, heat sinks, and other components for electronic devices.

● Mold Making: This includes the creation of complex molds for injection molding and other forming processes, wherein precision directly impacts the quality of the end products.

● General Manufacturing: Manufacturing of common components like gears, shafts, nuts, bolts, flanges, etc., used in a variety of industrial applications.

CNC Router Pros and Cons

Pros

Speed and Efficiency: For machining certain materials, CNC routers can be much faster than other technologies, enabling quick and efficient production times and higher throughput.

Lower Start-Up Cost: CNC router machines generally have a lower start-up cost than milling machines, making them more attainable for small businesses and hobbyists.

Flexible for Soft Feed Material: Great for cutting wood, plastics, foam, and mild metals like aluminum.

Continuous Operation: Once running, operates continuously for indefinite periods with minimal to no loss of accuracy or scalability at no extra cost.

Cons

● Limited Material Joules: Of lower torque and less rigid construction, making it less effective with harder materials (like steel or titanium).

● Less Precision: CNC mills are far superior for complex jobs that require accuracy and tight tolerances.

● Dust and Residue: They create a lot of dust and residue and will need to be effectively extracted.

CNC Milling Machines Pros and Cons

Pros

● High Precision: High accuracy and tight tolerance ability to manufacture complex components.

● Material Versatility: Machinable on a variety of materials, including but not limited to soft aluminum to hardened titanium and stainless steel.

● Sturdy build: The rigid design limits vibration and minimizes deflection, which gives developers superior surface finishes and dimensional accuracy.

● More Z Axis Depth: More significant material removal and allows thicker stock.

● Complexity in Geometry: Force vector path multi-axis capabilities make possible the production of complex 3D shapes and textures.

Cons

● Invest More Money: Much higher upfront costs than CNC routers.

● Operates Slower: In some applications, machining times would take longer due to lower RPM operation.

● Reduced Work Envelope: Generally, has a smaller workpiece limit than the larger bed size of CNC routers.

How to Choose Between a CNC Router and Milling Machine

Material Type

The materials you plan to work with should be a primary consideration in your decision.

● Choose a CNC router if you'll primarily be working with wood, plastics, foam, or soft metals like aluminum.

● Opt for a CNC mill if your projects involve harder metals like steel, stainless steel, or titanium, or if you need to machine materials with exceptional hardness.

Project Size and Scope

Consider the dimensions of your typical workpieces.

● A CNC router is preferable if you need a larger work surface for processing sheet materials or creating large-format items.

● A CNC mill might be better if your projects are smaller but require deeper cutting capabilities or more complex three-dimensional features.

Precision Requirements

Assess how critical dimensional accuracy is for your applications.

● If your projects can tolerate moderate tolerances and don't require extremely fine details in hard materials, a CNC router may be sufficient/

● If you need tight tolerances, superior surface finishes, or intricate features in tough materials, a CNC mill is the better choice.

Budget Constraints

Consider both initial investment and ongoing operational costs.

● CNC routers offer a lower entry point and generally less expensive operation, making them suitable for businesses with limited capital or those just starting out.

● CNC mills represent a larger investment but may provide better long-term value for applications requiring their specific capabilities.

Production Timeline

Think about your production speed requirements.

● CNC routers operate at higher speeds and can process softer materials more quickly, making them advantageous for higher-volume production of appropriate items.

● CNC mills work more slowly but can handle materials and operations that routers cannot, so the timeline must be balanced against capability requirements.

Conclusion

Hope this article helps you in your selection between CNC Router and Milling Machines based on your manufacturing requirements, material, precision, and budget. In this comparison, we have shown you the main differences between these two CNC technologies.

Have questions about CNC machines? Exploring the right option for your specific application is crucial, and consulting with industry professionals can provide valuable insights tailored to your unique requirements. Consider reaching out to manufacturers or visiting showrooms to see these machines in action before making your final decision.