In the production of plastic woven valve bags, the printing process directly affects the appearance, texture and market competitiveness of the product. As the core equipment for printing plastic woven fabrics and composite films, the "satellite" and "stacked" layouts of web-fed gravure printing machines have different focuses in the field of plastic woven valve bags. Gachn will focus on the characteristics of these two models in the printing of plastic woven valve bags to help you find a more suitable production tool.

Plastic woven valve bags are widely used in chemical, building materials, food and other industries because of their moisture resistance, load-bearing and sealing properties. The printing substrate is mostly plastic woven fabric (PP/PE woven fabric). The surface of this type of material is relatively rough, the thickness is relatively uniform, but there is a certain degree of ductility, which puts forward special requirements for the adaptability of printing equipment. According to the arrangement of the printing unit, the mainstream gravure printing machine is divided into satellite type and stacked type, and both have their own advantages in the production of plastic woven valve bags.

1. Satellite web-type gravure printing machine: the "stabilizer" for high-precision printing of plastic woven valve bags

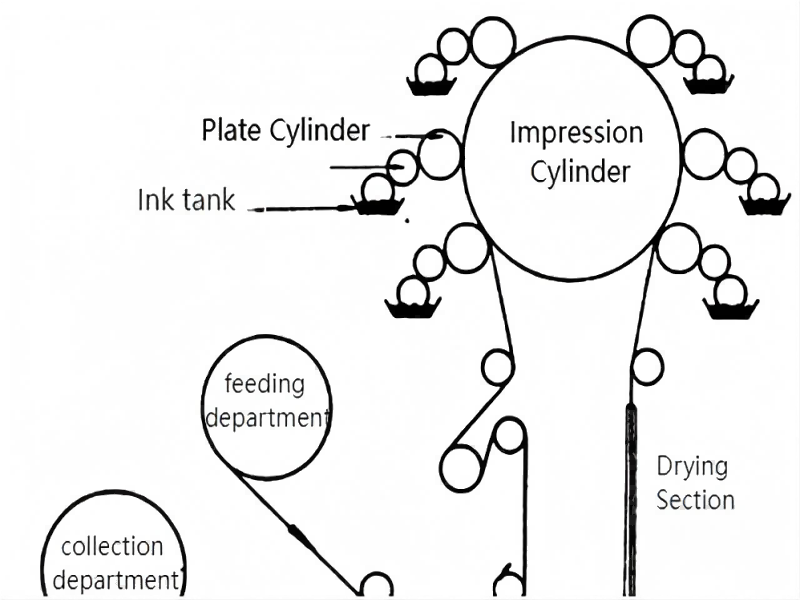

The satellite structure, with its "all stars around the moon" layout, is ideal for printing plastic woven valve bags that require high overprint accuracy.

Core structure

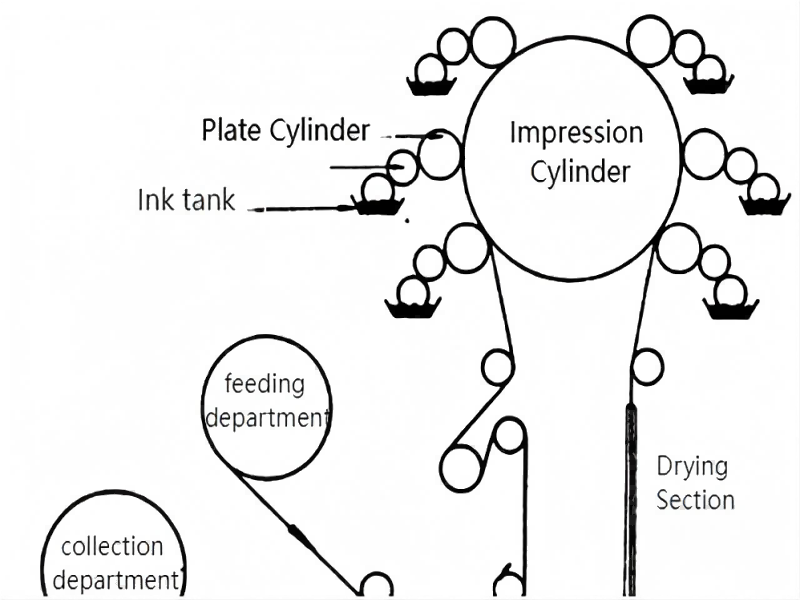

All gravure plate cylinders are arranged around a central impression cylinder, like satellites around a planet. For plastic woven valve bag printing, 4-6 printing units are usually configured to meet the multi-color pattern requirements of most products.

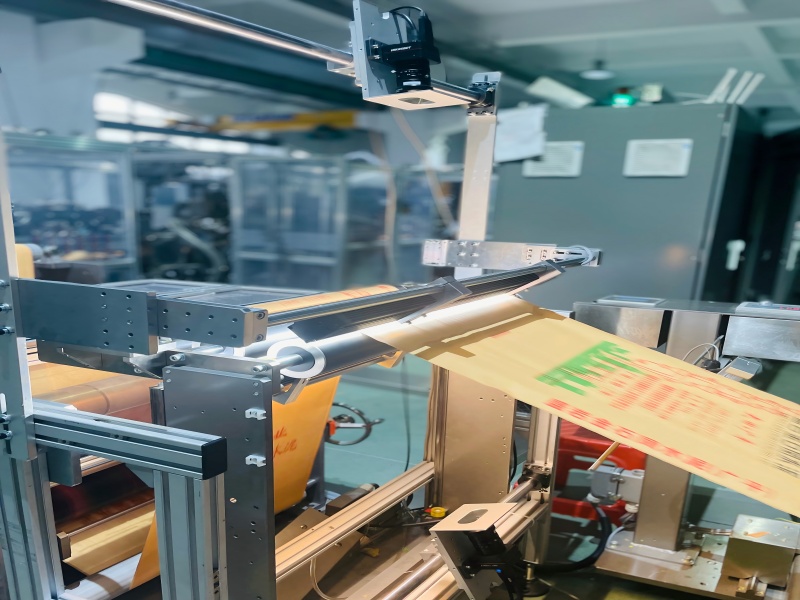

Workflow

After the plastic woven base material (woven fabric or composite woven film) is unwound from the feeding section, it enters the printing area through the tension control roller, closely adheres to the surface of the central impression cylinder, and passes through each printing unit in turn to complete multi-color overprinting. For valve bags that need double-sided printing (such as brand patterns on the front and product instructions on the back), the reverse printing device can be used to achieve efficient production of "single-sided single color + other side multi-color", and finally rewound into rolls by the receiving section.

The core advantages of plastic woven valve bags

(1)High overprinting accuracy and fit to rough surface: There are warp and weft lines on the surface of plastic woven fabric. The satellite-type central embossing roller is rigid, which can make the substrate evenly stressed and reduce the overprinting deviation caused by the unevenness of the woven layout. It is especially suitable for printing valve bags with fine text, QR codes or complex patterns (such as warning signs of chemical products and brand logos of grain packaging).

(2)Reduce substrate stretching deformation: Although the ductility of plastic woven fabric is lower than that of film, it may still be slightly stretched due to uneven tension during high-speed printing. The satellite-type single roller transmission throughout the whole process greatly reduces the risk of stretching and avoids "elongation" or "misalignment" of the pattern.

(3)Stability is suitable for mass production: Plastic woven valve bags are mostly batch orders. The satellite-type single embossing point reduces tension fluctuations, which can ensure the consistency of long-term continuous printing and reduce the scrap rate.

Limitations in the field of plastic weaving

(1)Drying efficiency is challenging for thick substrates: woven fabrics and composite films absorb a large amount of ink, while the satellite unit spacing is short, and the drying space for solvent-based inks is limited. A powerful drying system (such as high-temperature hot air circulation) is required, otherwise "smudge" problems may occur.

(2)Maintenance adaptability is slightly weaker: In woven printing, the printing plate is easily attached to the fluff of the woven fabric and needs to be cleaned frequently. However, the compact structure of the satellite results in a small operating space, and the cleaning and plate changing efficiency is slightly low.

Applicable to plastic woven valve bag scenarios

(1)Industrial-grade valve bags (such as cement bags and chemical raw material bags) made of thick woven fabrics or coarse textured substrates;

(2)Customized orders requiring complex patterns with more than 8 colors or special processes (BOPP lamination);

(3)Manufacturers that print valve bags with a width of ≥1 meter, or that produce multiple substrates such as paper and non-woven fabrics.

2. Stacked web-feed gravure printing machine: a versatile tool for flexible production of plastic woven valve bags

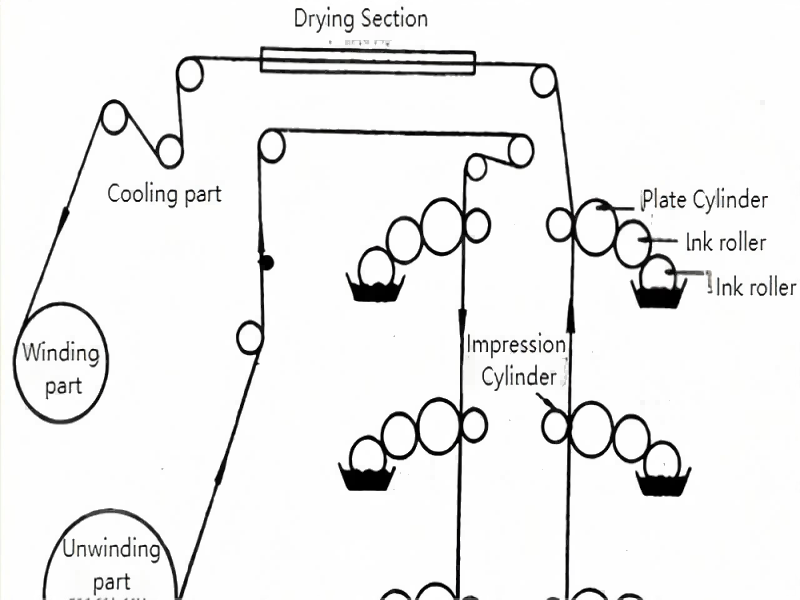

The stacking type is designed with independent units like "stacked" and is more flexible in the diversified production of plastic woven valve bags.

Core structure

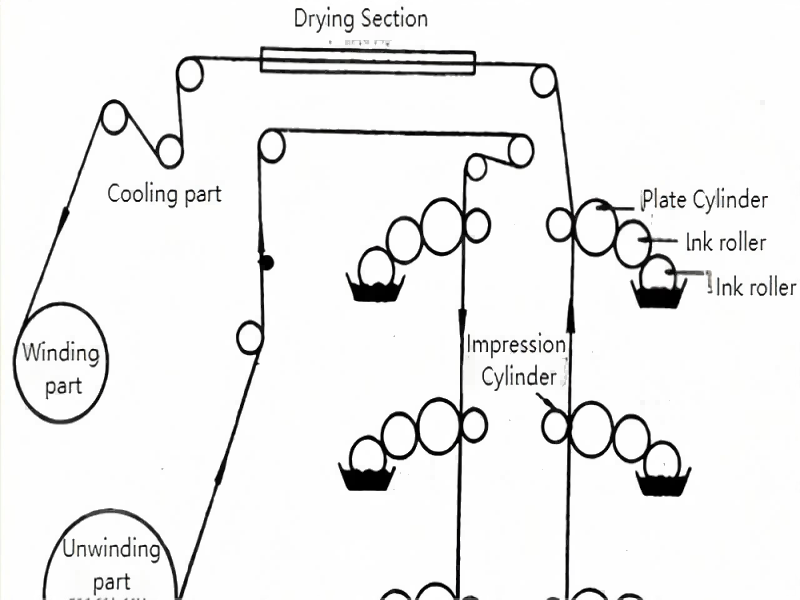

The printing units are stacked vertically on the main wallboard, and each unit is equipped with an independent impression cylinder, which is uniformly driven by a gear system. For the plastic woven industry, 2-8 color groups can be flexibly configured, and even auxiliary units such as cold stamping and lamination can be added.

Workflow

After unwinding, the plastic woven substrate passes through the stacked printing units in sequence according to the preset path, and each unit completes one-color printing. Due to the large spacing between units, there is enough space for the substrate to pass through the drying device after printing before entering the next color group. The receiving department can choose ordinary rewinding or reserve tension for subsequent bag making processes according to needs.

Core advantages of plastic woven valve bags

(1)Fully dried, suitable for thick substrates: plastic woven cloth absorbs a large amount of ink, the stacked unit spacing is wide, and a multi-stage drying system (such as infrared preheating + hot air drying) can be installed to ensure that the ink is thoroughly dried, especially suitable for industrial valve bags printed with solvent-based inks.

(2)Easy operation and maintenance: The independent unit design makes plate changing and cleaning more convenient. When dealing with the common "fluff pollution" problem in plastic woven printing, the machine can be quickly stopped for cleaning to reduce production interruption time.

(3)Flexible expansion to meet customized needs: plastic woven valve bags often need to add color groups (such as 8-color complex patterns) or add special processes (such as local UV varnish to improve wear resistance) according to customer requirements. The stacked type can be easily expanded and configured to adapt to small batches and multiple batches of customized orders.

(4)Adapt to wide-format substrates: For printing of large-size valve bags (such as width ≥1 meter) in the chemical and building materials industries, the stacked type has more advantages in wide-format stability.

Limitations in the field of plastic weaving

(1) High requirements for tension control for overprinting accuracy: Plastic woven fabrics are transferred between multiple independent impression cylinders over a long path. Improper tension control may cause overprinting deviations, and a high-precision tension control system (such as magnetic powder brake + tension sensor) is required.

(2) Increase in equipment height workshop requirements: The vertical stacking structure results in a high equipment height, and it is necessary to ensure that the workshop has sufficient floor height (usually ≥4 meters).

Applicable to plastic woven valve bag scenarios

(1)Industrial-grade valve bags (such as cement bags and chemical raw material bags) made of thick woven fabrics or coarse textured substrates;

(2)Customized orders requiring complex patterns with more than 8 colors or special processes (BOPP lamination);

(3)Manufacturers that print valve bags with a width of ≥ 1 meter, or that produce multiple substrates such as paper and non-woven fabrics.

3. Satellite type vs. stacked type: comparison of core indicators of plastic woven valve bag printing

|

Comparison Dimension

|

Satellite

|

Stacked

|

|

Core Advantages

|

High overprint accuracy, suitable for fine patterns; strong batch stability

|

Complete drying, suitable for thick substrates; flexible operation and easy expansion

|

|

Typical color group

|

4-6 colors (meet most common patterns)

|

2-8 colors (expandable to more than 10 colors)

|

|

Equipment maintenance

|

Small space for changing plates/cleaning, a bit cumbersome when frequent

|

Independent unit, easy to operate and low maintenance cost

|

Conclusion: The key to selecting plastic woven valve bag printing

Satellite and stacked gravure printing machines are not "either this or that" in the production of plastic woven valve bags, but "precisely matched" according to product requirements. If your order focuses on fine patterns, thin composite substrates, and batch stability (such as food-grade valve bags), the satellite type is the first choice to ensure quality; if it focuses on thick substrates, multi-color customization, and wide-format production (such as industrial ton bag valve mouth printing), the stacked type can better improve production flexibility. In the plastic woven valve bag industry, the core of equipment selection is "adapting product characteristics and order models" - only by understanding the essential differences between satellite and stacked types can the printing process become a plus point to enhance product competitiveness. To learn more, click on the official website to contact us.