In today's increasingly competitive global packaging industry, companies are increasingly demanding efficient, precise, environmentally friendly, and intelligent production equipment. As a professional valve bag making equipment manufacturer, our FK008 valve bag making machine, with its leading automation technology, stable and reliable performance, and future-oriented intelligent features, has become an ideal choice for customers in the building materials, chemical, grain, and plastic weaving industries.

Pioneering a New Era in Valve Bag Making Equipment: Discover the Benchmark Technology of the FK008-III Valve Bag Making Machine

We are proud to introduce the advanced FK008 valve bag making machine, whose features and performance meet industry-leading standards, providing customers with a more stable, efficient, and intelligent packaging production experience.

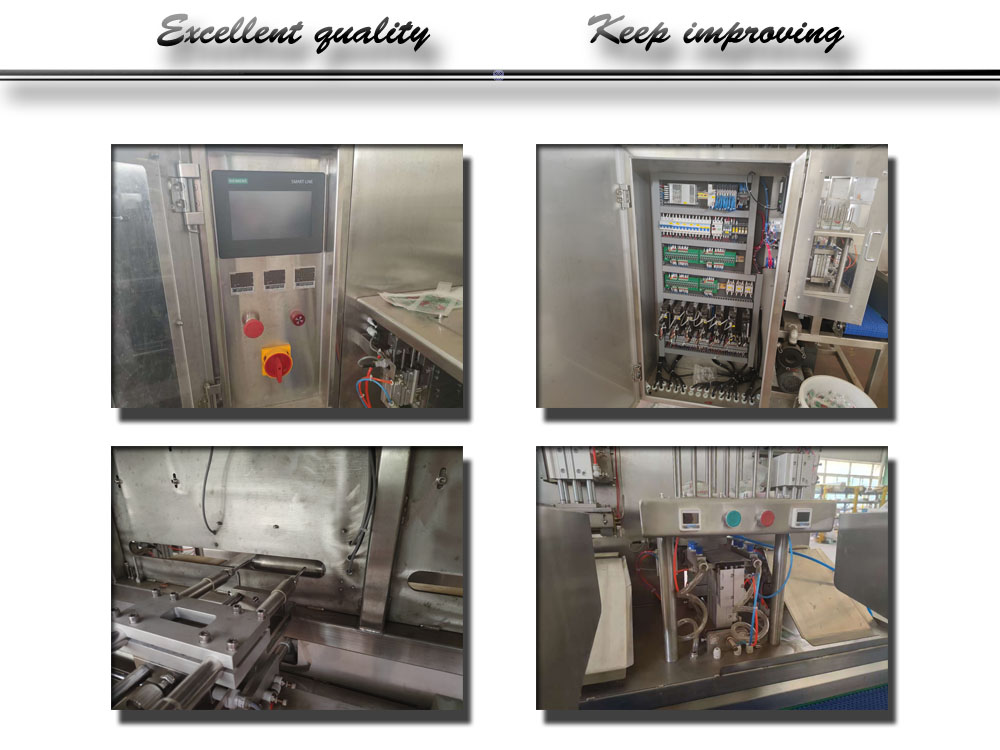

1. Fully Servo Driven, the Perfect Combination of Speed and Precision

The Gachn Gourp FK00-III valve bag making machine utilizes a fully servo control system, offering greater flexibility and precision than traditional mechanical drives. It can achieve a stable bag-making speed of up to 120 bags per minute while maintaining a tolerance of ±0.5mm. Whether it's large-volume orders or demanding customized packaging, it can easily handle them.

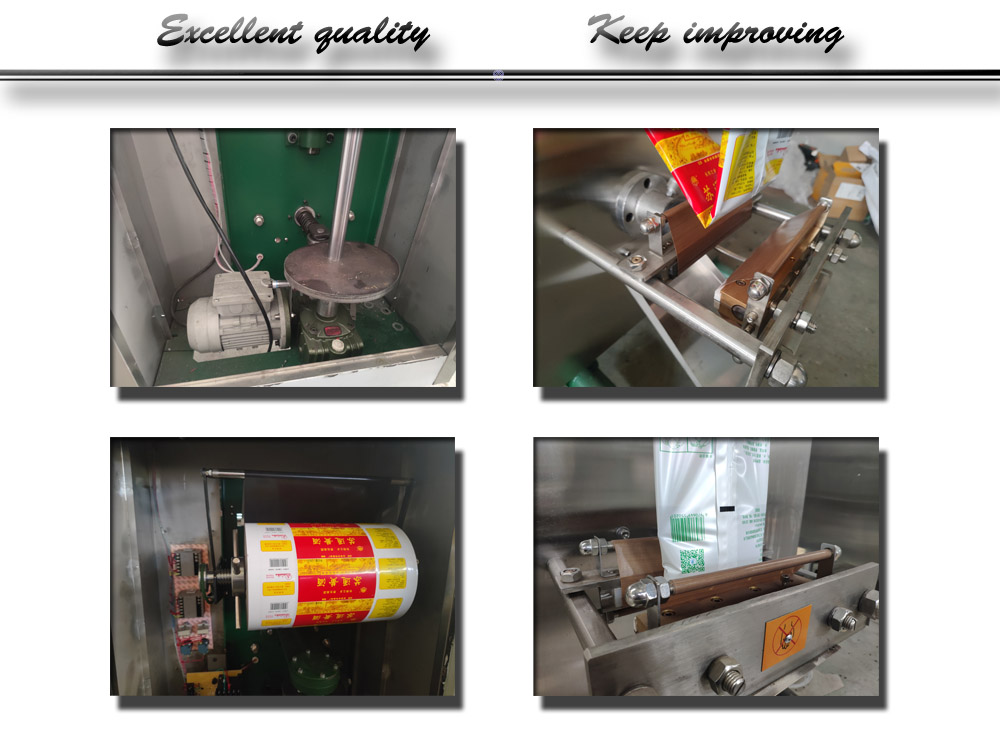

2. World-Leading Web Guide and Unwinding System

The machine is equipped with an imported web guide to ensure the bag's center position remains stable during high-speed operation, with deviations controlled within ±1mm. Passive unwinding combined with magnetic powder braking ensures a stable material supply, reducing waste and downtime.

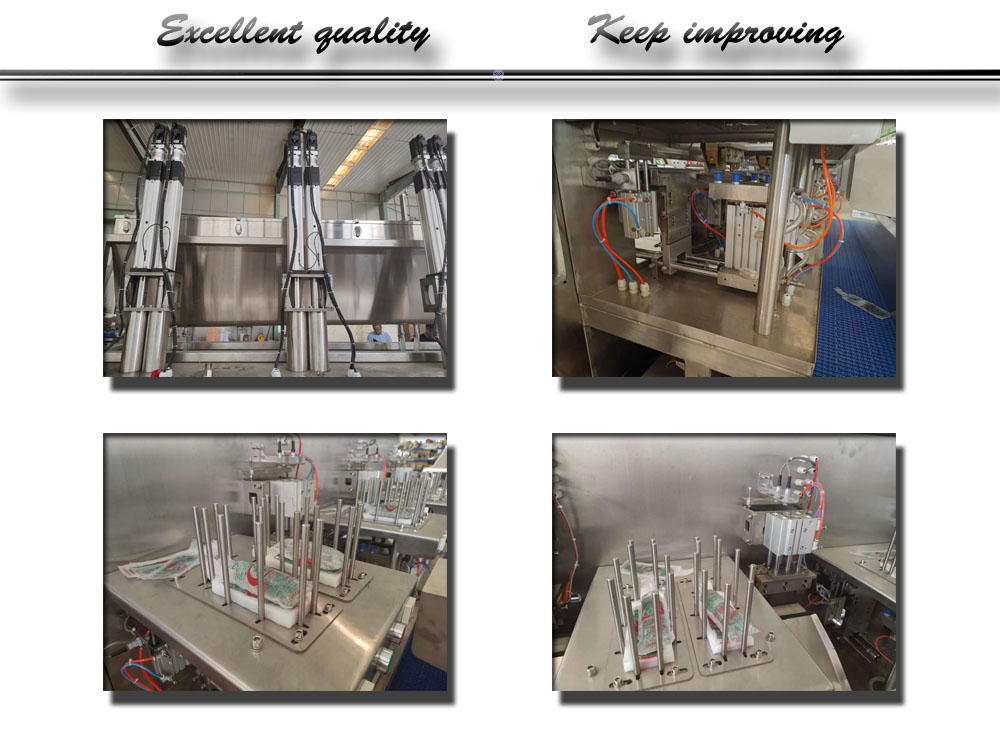

3. Patented Bag Opening Mechanism for Stable and Efficient Operation

The FK008 features a patented bag-opening technology. Unlike other bag-making machines, the Gachn Gourp FK008 utilizes a negative pressure blower and servo lever to ensure a smooth opening of the bag, avoiding common bag breakage or uneven openings. This innovative design combines high efficiency with low maintenance, significantly improving production continuity.

4. Optimized Heat Sealing and Forming Processes

Using constant temperature control and hot air welding technology, the temperature is stable and reliable, ensuring beautiful and strong welds. The triangular forming device and adjustable folding mechanism ensure smoother bag opening formation and adaptability to different bag shapes.

5. Intelligent Monitoring and Remote Diagnosis

The equipment features a built-in data monitoring system and optional cloud-based remote diagnostics. Users can not only monitor production status in real time, but also perform remote troubleshooting and maintenance, greatly improving equipment management efficiency and reducing the risk of downtime.

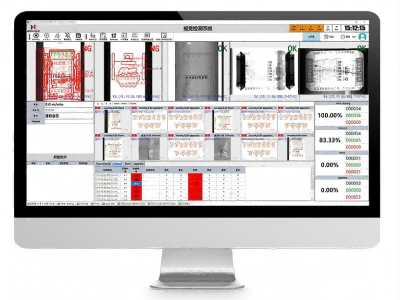

6. High-Precision Visual Inspection System

The FK008 can be equipped with an optional 4K industrial camera for visual inspection, enabling real-time monitoring of bag surface and bag opening quality. Its rejection accuracy exceeds 96.5%, with a false rejection rate below 0.15%, ensuring that every valve bag leaving the factory meets high quality standards. 7. User-Friendly Design for Easier Operation

A fully graphical user interface allows for intuitive parameter adjustment and is equipped with a safety protection system and fault alarm system. If any safety door is opened, the machine will immediately shut down, ensuring operator safety.

FK008 Valve Bag Making Machine: Beyond Innovation

Learning from the Gachn Group's extensive experience in packaging technology, our FK008 valve bag making machine is a cost-effective and practical professional solution for customers seeking high returns and consistent quality.

Core Feature 1: Comprehensive Performance Comparable to Benchmark Systems

Equipped with a high-precision visual inspection system (4K industrial camera), it achieves a rejection accuracy of at least 96.5% and a false rejection rate below 0.15%, essentially matching the automatic screening function of the qualiSTAR II.

Feature 2: Comprehensive Automation and User-Friendly Design

A fully servo-driven system enables quick and flexible format changes and adjustments.

A passive unwind combined with an inboard web guide maintains stable feed rates with an error of less than ±1 mm. A comprehensive safety system ensures safe operation and reliable processes.

Feature 3: Modularity and Easy Maintenance

The microperforation, bag opening, folding, and welding mechanisms utilize adjustable, modular, or servo-controlled structures, simplifying replacement and maintenance.

An early warning system and floating tension control ensure continuous production and minimize downtime.

Feature 4: Independently Developed and Patented, Legal and Compliant for Greater Peace of Mind

Unlike some copycat equipment, the FK008 valve bag making machine boasts a completely independently developed patented design encompassing key aspects such as the bag opening mechanism, forming process, and control system.

Legal and Compliant: Avoids the risk of patent infringement, ensuring customer investment security.

Technological Innovation: Provides unique solutions to the pain points of valve bag production.

Long-Term Guarantee: Customers can confidently export to global markets without being restricted by intellectual property barriers.

Drawing on industry-leading converting line technology, Gachn Group's FK008 valve bag making machine truly combines professionalism and reliability with high cost-effectiveness and practicality. Whether you prioritize stable production, high output, or seek intelligent automation and easy maintenance, the FK008 will meet and exceed your expectations. We look forward to helping you reach new heights in intelligent packaging and lead the market. If you would like further technical support or English promotional materials, I'm always here to assist you!