Full-Industry-Chain OEM Nicotine Pouch Solutions One-Stop Service from Raw Material to Finished Product

2026-01-27

Full-Industry-Chain OEM Nicotine Pouch Solutions: One-Stop Service from Raw Material to Finished Product

Large-Order Acceptance 600T Capacity for OEM Nicotine Pouch to Meet Large-Scale Demands

2026-01-27

Large-Order Acceptance: 600T Capacity for OEM Nicotine Pouch to Meet Large-Scale Demands

In the fast-growing Nicotine Pouch market, scaling your business often means facing tough challenges: missed market windows due to delayed production, inconsistent quality that hurts brand reputation, or inability to meet sudden surges in demand—issues even top players like Zyn and Velo once overcame with reliable manufacturing partners. If you’re ready to skip these pain points and jump straight to large-scale growth, HENO’s 600T annual capacity for OEM Nicotine Pouch is your solution.

1. Capacity That Matches Your Ambition

Forget production bottlenecks: HENO runs 12 fully automated Nicotine Pouch production lines, with a daily output of up to 1.5 million units—enough to fulfill a 10-million-unit order in just 7 days. Our 600T annual nicotine raw material reserve (paired with in-house 99.9% pure nicotine production) ensures no supply chain gaps, even during peak seasons when many manufacturers struggle to keep up. This is the same stable capacity that helps brands compete with industry leaders like Zyn and Velo in high-demand markets.

2. Quality That Meets Global Standards (Just Like Zyn & Velo)

Consistency is non-negotiable for Nicotine Pouch brands—and HENO delivers it through a 360° quality control system. Our 100,000-class clean workshops (compliant with GMP and ISO 9001) and 256+ quality checkpoints cover every step: from raw material testing (nicotine purity, food-grade flavor safety) to finished product inspection (moisture control, nicotine content accuracy). The result? Nicotine Pouch batches that match the safety, taste, and shelf-life standards customers expect from top-tier brands like Zyn and Velo—critical for building long-term trust in markets like Europe and North America.

3. Customization to Stand Out in the Market

Large orders don’t mean sacrificing uniqueness. HENO’s OEM Nicotine Pouch service adapts to your brand’s needs:

- Flavor: 40+ options (from classic mint, berry to trending herbal and citrus, tested to rival Zyn’s flavor longevity)

- Nicotine Strength: 2mg-10mg adjustable (perfect for targeting light, moderate, and heavy users like Velo’s product line)

- Packaging: Custom aluminum foil pouches, eco-friendly paper boxes, or blind-box designs—with fast sampling (7 days for prototype) to test market response before full production.

- Compliance: We handle EU TPD, US PMTA, and UK MHRA certifications, so your Nicotine Pouch can launch directly in key markets without delays.

Precision-Instrument Tested OEM Nicotine Pouch High Purity & No Microbial Contamination

2026-01-27

Precision-Instrument Tested OEM Nicotine Pouch: High Purity & No Microbial Contamination

Embark on a New Journey, Bring Good Fortune with Your Bags! Xiamen Gachn Group's Bag Making Machines Help You Seize the 2026 Packaging Market Opportunities

2026-01-23

I. Saying Goodbye to the Old and Welcoming the New: Say Goodbye to Production Bottlenecks and Embrace the Intelligent Future

Efficiency Challenges: Tight production capacity during peak order seasons, traditional equipment speeds reaching their limits?

Quality Control Concerns: Manual inspection inevitably leads to oversights, quality issues causing customer complaints and losses?

Cost Pressures: Continuously rising raw material and labor costs, constantly squeezing profit margins?

Management Complexities: Production data relies on manual recording, lacking digital insights to optimize decision-making?

The brand new year of 2026 should not be a continuation of old challenges. It's time to equip your factory with a "smart bag making expert" to confidently address market uncertainties.

II. New Equipment for the New Year: FK008 Smart Bag Making Machine, Your "Hardcore Weapon for the New Year"

The FK008 is not just a piece of equipment, but a strategic partner for achieving a three-in-one upgrade of cost reduction, efficiency improvement, and quality enhancement.

1. **Efficiency Bonus:** Full Servo Drive for Both Speed and Stability

Like a train speeding forward in the New Year, the FK008 is equipped with a full servo drive system, achieving a stable operating speed of 120 bags/minute and a peak speed of 130 bags/minute. This helps you quickly process orders, deliver on time, win customer trust, and get off to a good start in the new year.

2. **Intelligent Vision: Giving Every Bag a "Sharp Eye"**

Say goodbye to reliance on human eye fatigue detection. The FK008 can be equipped with a high-speed vision inspection system, acting like a tireless "quality inspector," achieving a high-precision control with a rejection rate of <0.15%. This ensures flawless products leaving the factory, protects your brand reputation, and makes your New Year business "stable and secure."

3. **Top-Tier Configuration for Long-Term Production**

We understand that stable operation is the best blessing. The core components of the FK008 use international brands such as Schneider PLCs, SMC pneumatics, and Japanese SHIMPO reducers, ensuring the equipment remains reliable and durable even under long-term high-load operation. Reduce unplanned downtime and ensure your production schedule runs smoothly, just like your New Year's agenda.

4. Usher in a New Era of Intelligence: Data Interconnection

For Transparent Production The journey to Industry 4.0 begins with digital productivity. The FK008 features data monitoring and interfaces, reserving space for future integration with higher-level MES systems. Let production data become your "New Year's blueprint" for optimized decision-making and unlocking potential.

III. New Year, New Services: Comprehensive Support for a Smooth Start

Choosing Gachn means gaining much more than just a top-of-the-line machine:

Professional "Start-up" Training: On-site engineer training ensures your team quickly masters the equipment.

Solid "Safeguard" Warranty: Comprehensive warranty and technical support services.

Continuous "Upgrade" Support: Continuous technical updates keep your equipment up-to-date.

Invest in the Future, Win the Start

The market competition of 2026 begins with this strategic planning. Investing in the FK008 intelligent bag-making machine is an investment of confidence in your business's future and the most valuable New Year's gift for your company.

In this hopeful season, let's join hands and move forward!

Book your exclusive New Year online demo and special offer consultation now!

The first 10 clients to consult will receive a complimentary 【2026 Production Optimization Planning Service】!

Let's work together to create a more efficient, intelligent, and prosperous new landscape for packaging in 2026!

From Efficiency to Quality A Comprehensive Analysis of Common Issues with the FK008-Ⅲ Valve Bag Making Machine, Unlocking New Possibilities in Packaging Production

2026-01-23

In the PP woven valve bag production field, the bag making machine, as the core terminal equipment, directly determines the product qualification rate, production efficiency, and overall cost. Xiamen Gachn Group, with over ten years of experience in the industry, has independently developed the FK008-Ⅲ valve bag making machine, which, thanks to its patented technology, intelligent configuration, and stable performance, has become the choice of over 50 projects worldwide. Today, we've compiled the 10 most frequently asked questions from customers, providing a comprehensive breakdown of the core advantages and key usage points of this equipment, from technical parameters to practical applications.

I. Core Configuration and Performance: These Key Parameters Directly Affect Production Efficiency

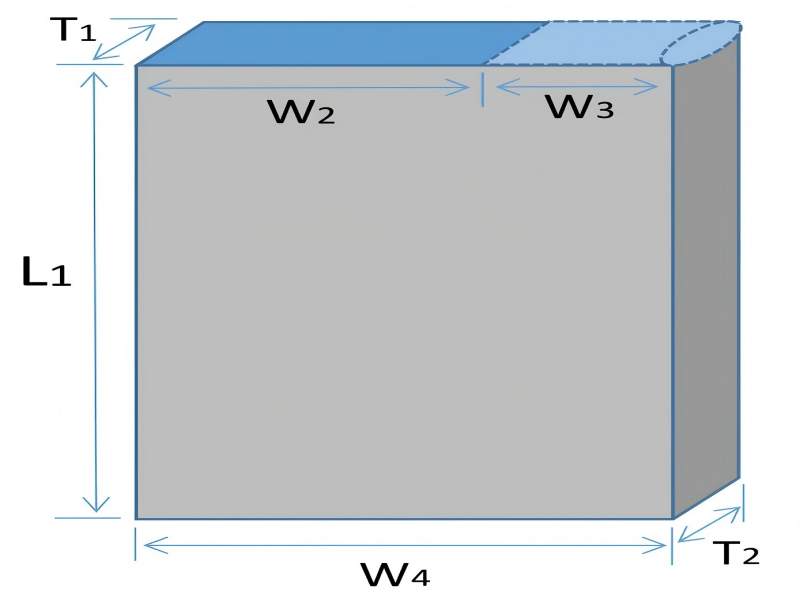

Q1: What specifications of valve bags can the FK008-Ⅲ produce? What are its applicable scenarios?

A: This equipment primarily produces PP woven single-layer coated valve bags, covering capacity requirements from 10-50kg. Specific specifications are as follows: bag width (W1) 300-620mm, inner valve width (W3) 80-200mm, outer valve width (W4) 130-300mm, bag length (L1) 360-750mm, fully meeting the packaging needs of industries such as chemical, cement, grain, and building materials. It is currently operating stably in overseas markets such as Uzbekistan and Saudi Arabia, as well as in large-scale projects in Jiangxi, Guizhou, and Fujian provinces in China, adapting to the raw material characteristics and production standards of different regions.

Q2: How is the equipment's production efficiency and stability? Is it capable of continuous operation?

A: The FK008-Ⅲ achieves a stable production speed of 110-120pcs/min. Equipped with a full servo control system and internationally renowned brand components (Schneider PLC, NSK bearings, etc.), the dynamic error is less than 0.01mm, ensuring smooth sealing and precise dimensions even at high speeds. The equipment supports operation in a wide temperature range of -20℃ to 60℃. Its dust-resistant and voltage fluctuation-resistant design results in a failure rate of less than 0.5%, enabling 30 days of continuous, downtime-free production, making it particularly suitable for large-scale mass production.

Q3: Compared to ordinary bag-making machines, what are its advantages in cost control?

A: The core advantages are concentrated in two aspects: raw material savings and energy consumption optimization:

1. Patented bottom sealing technology: Utilizing single-sided film material and a narrow bottom overlap design, it saves $1 in raw material costs for every 500 bags produced. A production line with an annual capacity of 30 million bags can save $60,000 annually.

2. Intelligent energy-saving system: Vector frequency conversion technology reduces motor energy consumption by 10%-30%, automatically entering sleep mode during standby and intelligently boosting voltage under high load, saving tens of thousands of yuan in electricity costs annually.

3. AI visual inspection replaces manual labor: One operator can manage 3-4 machines simultaneously, reducing labor costs by 240,000-360,000 yuan per production line annually.

II. Technological Innovation and Patents: These Cutting-Edge Technologies Solve Industry Pain Points

Q4: What is the patented triangular bag opening technology? How is it superior to traditional designs?

A: This is Gachn's core innovation. It achieves bag opening formation through vacuum negative pressure, eliminating the need for easily damaged parts such as suction cups. Traditional bag-making machines' suction cups frequently contact materials, leading to wear, leakage, unstable bag opening formation, and high maintenance costs. The FK008-Ⅲ's contactless design not only offers faster forming speed and stronger stability but also reduces the replacement of easily damaged parts by 90%, lowering subsequent maintenance workload and costs.

Q5: What defects can the AI vision inspection system identify? What is its accuracy rate?

A: The system fully covers two major categories of problems: base fabric defects and bag-making defects. These include round threads, holes, coarse threads, joints, and scratches in the base fabric, as well as bottom sticker misalignment, sticker folding, missing corners, and incomplete sealing during the bag-making process. AI adaptively identifies defects without manual marking, achieving a false negative rate as low as 0.05%. Compared to manual inspection, the accuracy is improved by more than 3 times, and defect data can be tracked in real time, providing a basis for production process optimization.

Q6: Is the equipment highly automated? Does it require high skill levels from operators?

A: The equipment uses a user-friendly human-machine interface with a fully Chinese/English control panel. Parameter settings, fault warnings, production counting, and other functions are clearly displayed. Ordinary workers can operate it independently after 1-2 days of training, and the maintenance team only needs 2 mechanical engineers and 1 electrical engineer per shift. We also provide detailed Chinese and English operation manuals and video tutorials, and on-site training combines hands-on practice to ensure immediate usability upon production.

III. Installation, Commissioning, and After-Sales Service: Is the overseas project implementation guaranteed?

Q7: What are the installation and commissioning procedures after overseas customers purchase the equipment?

A: Gachn provides turnkey service with complete transparency throughout the process:

1. 100% full-machine testing is completed before equipment leaves the factory to ensure compliance with export standards;

2. Standard ocean-going packaging is used for sea freight, with a professional customs clearance team assisting with procedures;

3. Upon arrival at the site, 8 professional technicians provide on-site service, completing installation, commissioning, and trial production within 30 days;

4. During the trial production phase, parameters will be optimized based on actual output until the product qualification rate reaches the agreed standard before acceptance.

Q8: What does the training include? How is after-sales technical support guaranteed?

A: Training adopts a combined "theory + practice" model, covering equipment structure principles, daily operation, parameter adjustment, common troubleshooting, maintenance, etc., and customized training materials are also provided. Regarding after-sales support, the equipment enjoys a 12-month full-machine warranty (including electrical and mechanical systems), and free upgrades to the electrical control system within 3 years; whether domestic or overseas, the after-sales team will respond to fault inquiries within 24 hours, and in emergencies, technicians can be coordinated for on-site service.

Q9: What are the requirements for the factory and supporting facilities for the equipment?

A: The space required for a single unit is 12m long × 7.5m wide × 2.5m high. It is recommended that the entire production line factory be no less than 85m × 60m (including equipment placement and material handling area). Supporting facilities must meet the following requirements: 380V three-phase five-wire power supply (total power 150KW, operating power 60KW), 0.6m³/h cooling water flow, and 6-7 bar compressed air (3m³/min). These are standard configurations for conventional industrial production; customers can prepare them in advance according to their own circumstances.

IV. Practical Application and Expansion: These Details Help You Avoid Production Risks

Q10: Does the equipment have special requirements for raw materials? Is it compatible with PP raw materials from different regions?

A: Raw materials must meet the following standards: PP drawing grade raw materials (MFI 3.5-5.0g/10min, 230℃), coating grade raw materials (PP coating grade MFI 18-40g/10min, or 85% PP + 15% LDPE mixed raw materials). Additives can include conventional auxiliaries such as calcium carbonate masterbatch. Our equipment is adapted to the characteristics of raw materials in different regions worldwide. In the early stages of a project, we will conduct targeted adjustments based on the raw material samples provided by the customer to ensure stable production of qualified products even with slight fluctuations in raw material indicators.

Further Consideration: Why are more and more overseas customers choosing Gachn's bag-making machines?

Besides the technological advantages of the equipment itself, comprehensive full-industry chain support is key: Gachn can provide complete line solutions from drawing, circular weaving, coating, printing to bag making, avoiding compatibility issues between different brands of equipment; 200+ national patents (including 28 invention patents) ensure no technology infringement risks; extensive overseas project experience and familiarity with customs policies, industrial standards, and service requirements in different regions make project implementation smoother.

If your company is planning a valve bag production line or wants to upgrade your existing bag making equipment, feel free to contact us for a customized solution! Fill out the consultation form below, and our technical consultants will provide you with equipment selection advice, capacity calculations, and detailed quotations within 48 hours. You can also get a free FK008-Ⅲ equipment operation video and a success story manual.

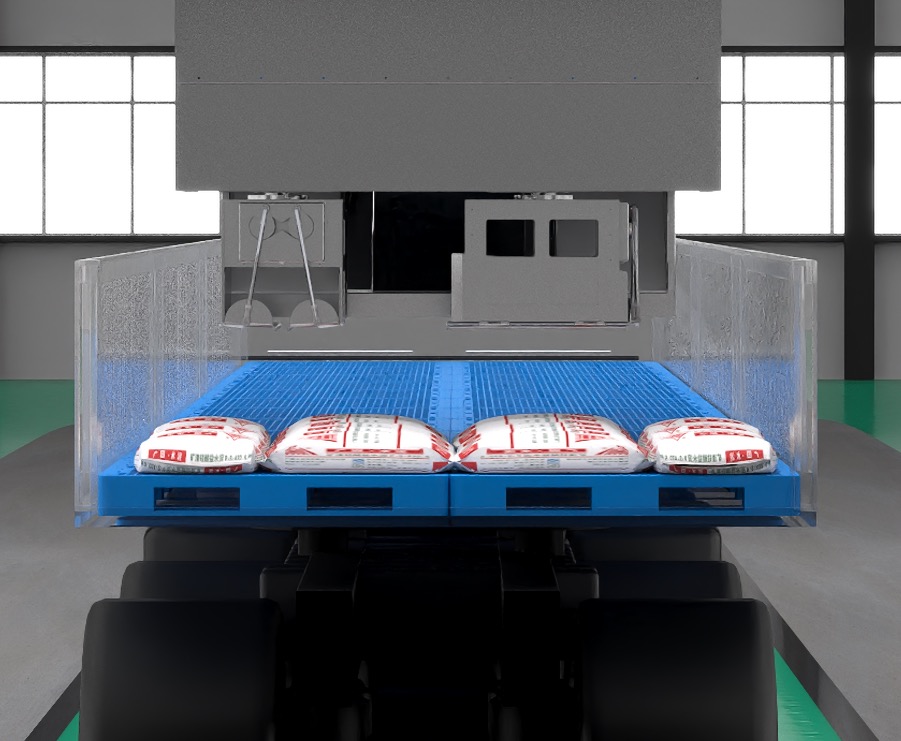

World's first intelligent loading machine for trucks

2026-01-23

In the wave of intelligent transformation in the cement industry, the "last mile" of the shipping process has always been a pain point for many companies. Low efficiency of manual loading, severe dust pollution, reliance on manual labor for high-sided trucks, and chaotic vehicle dispatching management... these problems not only drive up operating costs but also become bottlenecks restricting enterprise development. Today, Xiamen Gachn presents the world's first "in-cargo" intelligent cement loading machine, which, with its revolutionary design and superior performance, is bringing a profound revolution to the industry.

Saying Goodbye to Industry Maladies: Three Major Pain Points of Traditional Loading Modes

For a long time, neither traditional robotic arm solutions nor early palletizing solutions have fundamentally solved the core problems of cement loading.

Efficiency Bottleneck: The actual effective loading efficiency of most traditional equipment hovers around 70-80 tons/hour, and its poor stability makes it difficult to match the capacity of modern cement packaging lines, becoming a key weakness restricting overall production efficiency.

Adaptability Limitations: Faced with the large number of high-sided freight vehicles in the market, traditional equipment is often "helpless," forcing automated loading lines to be interrupted, requiring manual intervention, and rendering intelligent systems useless. Environmental and Operational Pressures: High-level bag throwing or dropping generates massive amounts of dust, creating immense environmental pressure; the complex centralized structure leads to high failure rates, cramped maintenance space, and persistently high maintenance costs and downtime losses.

Key to the Solution: What is "In-Cargo (ICO)" Intelligent Loading?

The core of GIGABYTE's solution lies in its "In-Cargo" design concept. Unlike all traditional equipment that operates outside the truck bed, our intelligent loading machine innovatively extends the bag-stacking head directly into the truck bed for operation.

This fundamental change is like transforming "surgery" from an external operation to a minimally invasive intervention, resulting in a comprehensive leap in performance:

Eradicating Dust: With the bag-stacking head positioned low, the height difference between the cement bags and the truck bed floor is minimized, significantly suppressing dust generation at its physical source.

Conquering All Vehicle Models: Whether for low-sided or high-sided trucks, the machine head can easily operate deep inside the truck bed, achieving true seamless adaptation to all vehicle models and breaking down vehicle model barriers in automated loading.

More Stable Operation: The compact and direct operating method reduces long-distance, wide-range swinging of the robotic arm, resulting in smoother operation and a significantly lower failure rate.

Superior Performance Parameters, Setting a New Industry Benchmark

Our "in-carriage" intelligent loading machine not only boasts an advanced concept but also solid performance data supporting its outstanding performance:

Highly Efficient Output: The system's loading efficiency is perfectly matched with the packaging machine, stably achieving a high output of 90-100 tons/hour, fully releasing shipping capacity.

Precise and Fast: The packaging capacity reaches up to 120 tons/hour, and the packing speed reaches 40 packs/minute. Vehicle parking deviation is allowed to be ±120mm. Through a 3D LiDAR scanning system and a linear laser guide line, the system can intelligently guide and adapt, greatly reducing the precision requirements for driver parking and improving overall flow efficiency.

Flexible and Intelligent: Supports horizontal, vertical, and mixed palletizing modes. Through its independently developed JNGGZC-001-11 intelligent control and management system (based on the Schneider motion servo platform), it automatically calculates the optimal palletizing scheme based on vehicle type and tonnage, ensuring neat stacking and high space utilization.

Core Configuration for a Reliable Foundation: Top-tier performance stems from uncompromising commitment to core components:

Intelligent Brain: Employs a Schneider integrated control platform and servo drive system, ensuring precise control, rapid response, and reliable operation.

Sharp Eyes: A 3D LiDAR scanning system constructs a real-time 3D model of the vehicle, accurately identifying size, location, and foreign objects, providing a high-definition "vision" for intelligent decision-making.

Robust Limbs: Key power components such as the walking and lifting motors use Schneider brand products, ensuring power and stability under long-term high-load operation.

Safety Assurance: The entire machine is designed to meet stringent safety standards, with safety sensors and protection at key locations, and equipped with comprehensive pneumatic and dust removal interfaces.

Creating Comprehensive Customer Value

Choosing Gachn's "Box-Type" Intelligent Loading Machine will bring you value far exceeding the equipment itself:

Significant Economic Benefits: Increases shipping efficiency by over 30%, reduces loading manpower by 2-3 people per shift, and significantly reduces environmental treatment costs and maintenance downtime losses caused by dust.

Comprehensive Management Upgrade: Achieves unmanned, standardized loading, automates vehicle-cargo matching and data statistics, and seamlessly integrates with ERP/MES systems, driving the factory towards digital and intelligent management.

Social and Environmentally Friendly: Greatly improves the working environment for workers, significantly reduces fugitive emissions in the plant area, and helps enterprises achieve green and sustainable development goals.

Looking to the Future: Making Intelligent Loading a Core Competency

In the grand context of "Industry 4.0" and "Smart Manufacturing," intelligent back-end production is also a key element in building a company's core competitiveness. Gachn's world's first "Box-Type" intelligent cement loading machine is not only an advanced piece of equipment, but also a strategic fulcrum for building an efficient, clean, and intelligent modern cement plant.

We cordially invite you to delve deeper into this revolutionary solution and explore together how it can create tangible benefits for your business.

Take action now to schedule a private online demo or obtain a detailed technical solution.

CCD alignment system is used in screen printing

2026-01-14

CCD alignment system is used in screen printing to ensure accurate registration of colors and designs. CCD (Charge-Coupled Device) cameras are used to capture images of the printing surface and the printing screens. The images are then analyzed by software to determine the exact position of the printing screens in relation to the printing surface. This information is used to adjust the position of the screens to ensure that the colors and designs are printed in the correct location and with the correct registration. CCD alignment system is particularly useful for printing complex designs with multiple colors, as it ensures that each color is printed in the correct location and with the correct registration, resulting in a high-quality print.

For heat transfer label printing ,print glue and spraying hot melt powder ,which is better?

2026-01-14

For heat transfer label printing ,print glue and spraying hot melt powder ,which is better ?

both techniques have their advantages and disadvantages:

Printing Glue:Printing glue allows for precise application of heat transfer labels, which can result in high-quality and long-lasting prints. It also provides good adhesion to a wide range of substrates. However, it may be more time-consuming and can require specialized equipment.

Spraying Hot Melt Powder:

Spraying hot melt powder can be faster and more efficient than printing glue. It also provides a strong bond to various materials, including plastics, metals, and fabrics. However, it may not provide as precise control as printing glue, and the equipment and materials used can be more expensive.

Ultimately, the choice between the two methods will depend on the specific requirements of the project and the materials involved. Consider factors such as the type of substrate, the desired print quality, speed, and cost-effectiveness.

How does it works a rewinder machine?

2026-01-14

A rewinder machine is a machine that is used to wind a roll of material, such as paper, film, or tape, into a smaller roll or into a specific shape. There are several types of rewinder machines, including surface winders, center winders, and coreless winders, each of which operates slightly differently.

In general, a rewinder machine consists of a series of rollers or drums that the material is fed through, as well as a drive system that rotates the rollers or drums to wind the material onto a spindle or core. Some rewinder machines also have additional features, such as slitting or cutting systems, to cut the material into specific lengths or widths.

To operate a rewinder machine, the operator typically loads the material onto the machine and sets the desired winding parameters, such as the winding speed, the width of the material, and the size of the finished roll. The machine then winds the material onto the spindle or core, using the drive system and rollers or drums to control the tension and position of the material. Once the roll is complete, the operator can remove it from the machine and prepare it for use or storage.

Screen printing feature

2026-01-14

Screen printing Machine feature:

The printing platform is horizontal in and out, Adopt 4-post precision linear guider,high presicion Repeat register . more stable and durable;

Printing plate positioning standard accuracy +- 0.01mm ;

Double axis squeegee ,In the process of scraping, the pressure applied to the print by the squeegee is more uniform, and the printing effect is high and close ,

Advanced automatic tension adjustment system , Avoid sticking plates and shadows , But there is no general synchronization shortcomings ,Because of this kind of direct stretch cloth ,The act of leaving the fabric away from the print ,This may lead to an increase in the amount of deformation of the fabric ,Causing confusion or displacement of an ink image ,Frequency converter drive control, squeegee speed is stable and easy to adjust .

The advantages of screen printing:

Screen printing is the process of forcing ink through a screen with a stencil blocking off desired areas. Also known as silk-screen printing, screen printing is one of the many printing techniques available.

Better Quality That Lasts

One of the main advantages to screen printing is the vivid results it creates. The overall print quality of screen printing is generally considered higher than other types of printing. Furthermore, screen printing is a versatile printing option that works well on various objects and materials. On garments, the heat-dried ink used in screen printing is tough enough to handle repeat washings without fading or cracking.

Varying Price Range

Several factors affect the price of screen printing, and you should consider each aspect beforehand. Screen printing items yourself is generally a cheaper option when weighed against other home printing methods. However, when you hire a professional company to perform the task for you, the price can be a bit high, especially for small orders. This is usually due to a setup fee that the company charges in order to prepare the screens for printing the various colors. Screen printing is typically less expensive for larger orders.