Why Water-Cooled Screw Chillers Are Leading the Cooling Industry

Water-cooled screw chillers are the top choice in cooling systems. The market for these chillers will be worth over $4.8 billion in 2025. Big companies buy these chillers because they save energy, can grow with needs, and help the environment. Experts know it is important to watch new trends. Smart technology and new rules help people stay ahead in cooling system ideas.

-

Water-cooled screw chiller models use up to 30% less energy than old systems.

-

The market gets bigger as chillers show they work well for businesses and factories.

-

New ideas like modular design and predictive maintenance make more people use water-cooled screw chillers.

Water-Cooled Screw Chiller Basics

How Water-Cooled Screw Chillers Work

A water-cooled screw chiller cools big buildings and factories. It has two main loops. One is the refrigeration loop. The other is the chilled water loop. The refrigeration loop uses the vapor compression cycle. This cycle lets the refrigerant change between liquid and vapor. It helps absorb heat and then release it. The chilled water loop sends cold water to places that need cooling.

Here is how water-cooled chillers work step by step:

-

The screw compressor takes in low-pressure refrigerant vapor. It squeezes the vapor to make it hotter and under more pressure.

-

The condenser moves heat from the refrigerant to the cooling water. The cooling water goes to the cooling tower.

-

The expansion valve drops the pressure and temperature of the refrigerant.

-

The evaporator takes heat from the chilled water. This cools the water for the building or process.

-

The cycle starts again. This keeps cooling steady and efficient.

This process makes water-cooled screw chillers great for keeping temperatures stable in many places.

Key Components

Every water-cooled screw chiller has important parts. These parts work together to keep things cool:

|

Component

|

Role in Cooling Process

|

|

Compressor

|

Squeezes low-pressure refrigerant gas into high-pressure gas. This makes it hotter and helps move heat.

|

|

Condenser

|

Takes heat from the refrigerant and gives it to the cooling water. This turns the refrigerant into a liquid.

|

|

Expansion Valve

|

Lowers the pressure and temperature of the refrigerant. This helps it absorb heat better.

|

|

Evaporator

|

Takes heat from chilled water or fluid. This makes the refrigerant turn into vapor and cools the fluid.

|

|

Chilled Water Loop

|

Sends chilled water to places that need cooling.

|

|

Condenser Water Loop

|

Sends cooling water to take heat from the refrigerant. The water then goes to the cooling towers.

|

|

Water Boxes

|

Direct water flow in the evaporator and condenser. This helps heat exchange work better.

|

|

Power Unit

|

Controls the electricity for the chiller. It includes starters and circuit breakers.

|

|

Controls

|

Watch and change how the chiller works. They can make alarms and let people control the chiller remotely.

|

These main parts help water-cooled chillers work well, last long, and stay reliable in tough places.

Energy Efficiency Advantages

Water-cooled screw chillers are very good at saving energy. They use water to move heat. This helps them cool big buildings well. Using water makes them use less energy. It also helps building owners follow green rules. Experts use SEER, EER, and COP to check how well chillers work. These numbers tell us how much cooling comes from the power used. Lower approach temperatures mean the chiller works better.

Variable Speed Drives

Variable speed drives, or VSDs, help chillers save more energy. VSDs let the compressor change speed when needed. This means the chiller does not always run at full power. It uses less energy when cooling needs are low.

-

VSDs stop energy waste by slowing the compressor instead of turning it off and on.

-

Studies show VSD chillers use about 11% less energy each year than chillers that run at one speed.

-

In big buildings, VSDs can save over a million kilowatt-hours every year.

Tip: VSDs make chillers work better and last longer. They also help save money over time.

Advanced Heat Exchangers

Advanced heat exchangers help chillers move heat faster. New designs, like falling-film evaporators and special tubes, use less refrigerant and energy.

-

Hybrid evaporators mix old and new ideas for better cooling and less harm to the planet.

-

Stronger tube materials stop rust and help move heat better.

-

These changes let chillers reach COP values up to 4.98, showing they save a lot of energy.

Better heat exchangers also make chillers smaller. This saves space and helps them fit in tight spots.

Innovations in Water Cooled Screw Chiller Technology

IoT and Smart Controls

New water-cooled screw chillers use IoT and smart technology. These systems collect data like temperature and humidity. They also track how much work the chiller is doing. Smart controllers use this information to help the chiller work better. This makes the chiller use less energy and run more smoothly.

-

IoT lets chillers change quickly when things change.

-

Smart controls can cut energy use by half compared to old chillers.

-

One factory in Beijing used 25% less energy in a month after adding smart controls.

-

These systems watch the equipment and make small changes to keep things working well.

-

This means fewer problems and better control of temperature.

Facility managers need to check their systems before adding IoT. They should pick equipment that works with the new tech. Staff must learn how to use the new system. Regular checks and care, like fixing sensors and checking networks, keep things running well. More people want energy-saving and green systems, so smart chillers are becoming popular.

Note: IoT and smart controls are a big step for cooling systems. They help companies save money and have less downtime.

Sustainable Refrigerants

The industry now wants to use sustainable refrigerants to protect the environment. Old refrigerants like R-134a can harm the planet. New rules say companies must use greener choices. The U.S. SNAP program and some states, like California, limit high-GWP refrigerants in new chillers.

-

New refrigerants like R-454B, R-1234ze(E), R-1233zd(E), R-513A, R-515B, and R-32 have much lower GWP.

-

Some have GWP close to 1, so they are almost climate-neutral.

-

These new refrigerants help chillers work better and follow strict rules.

-

Most are not flammable or only a little flammable, so they are safer.

-

Top companies now sell chillers with these refrigerants to cut carbon without losing performance.

Natural refrigerants like ammonia, CO2, and hydrocarbons have very low GWP. But they can be harder to use because of safety and cost. Using better refrigerants shows how new ideas and rules are changing cooling.

Scroll Compressor Integration

Adding scroll compressors is another big change in water-cooled screw chillers. Now, some chillers use both screw and scroll compressors together. This is called a hybrid system. It uses the best parts of each compressor.

-

Scroll compressors are good when the chiller does not need to work as hard.

-

Screw compressors are better when the chiller needs to cool more.

-

Hybrid chillers can switch between the two or use both, depending on what is needed.

This design helps chillers use less energy and work better. It also makes chillers more reliable. Hybrid chillers can fit many building sizes and uses. These changes help chillers meet new needs and support a greener world.

Tip: Hybrid systems give more choices and save energy. They are a smart pick for new buildings and upgrades.

Water-Cooled Chillers Market Trends

Market Growth Drivers

The water-cooled chillers market is getting bigger as cities grow. More factories and buildings need better cooling. The global chillers market was $3.86 billion in 2024. It may reach $4.66 billion by 2032. This growth happens because cities are growing fast. More factories are being built. Old cooling systems need to be replaced. Asia-Pacific is the biggest market for chillers. It has over 40% of the market. Southeast Asia wants more water cooled chillers.

Many things help the water-cooled chillers market grow:

-

Water cooled chillers use less energy than air-cooled ones in big buildings.

-

New rules make building owners pick greener cooling systems.

-

Smart cooling systems, like IoT chillers, help save energy and watch equipment.

-

Hotter weather and bigger cities mean more cooling is needed.

-

More money and new buildings mean more chillers are needed.

-

Green buildings and saving money on energy keep the market strong.

Note: The water-cooled chillers market has some problems. These include high starting costs and not enough water. But smart tech and new refrigerants give good chances for growth.

Scalability and Application Range

Water cooled chillers are important for big jobs and factories. They use cooling towers outside to get rid of heat. They work at lower temperatures than air-cooled chillers. This makes them use less energy. They help keep places like factories, data centers, and hospitals cool.

Some main features of water cooled chillers are:

-

They can cool big places very well.

-

Their designs can be changed to fit many spaces.

-

They are quick to set up and do not stop work much.

-

They work in many different temperatures for many jobs.

A table below shows how water cooled chillers help in different places:

|

Application Area

|

Benefit of Water Cooled Chillers

|

|

Data Centers

|

High capacity, small footprint

|

|

Manufacturing Plants

|

Stable cooling for heavy equipment

|

|

Hospitals

|

Reliable temperature control

|

|

Commercial Buildings

|

Energy savings and easy scaling

|

Water cooled chillers are the best pick for city cooling systems. Their small size and easy design help big places add more cooling fast. As cities get bigger and the world gets hotter, water-cooled chillers will stay important for big, efficient cooling.

Overcoming Challenges

Water Management

Water-cooled screw chillers have some water problems. Corrosion happens when air, minerals, or germs get inside. If different metals touch, they can cause leaks. Dirt and small bits from bad water or dirty towers can block pipes. This makes it harder for the chiller to cool things down. These problems make the chiller less efficient and can break it.

-

Condenser tubes can get dirty from things in the water.

-

Buildup inside the tubes slows water and makes the chiller work more.

-

Cleaning with chemicals or brushes keeps the chiller working well.

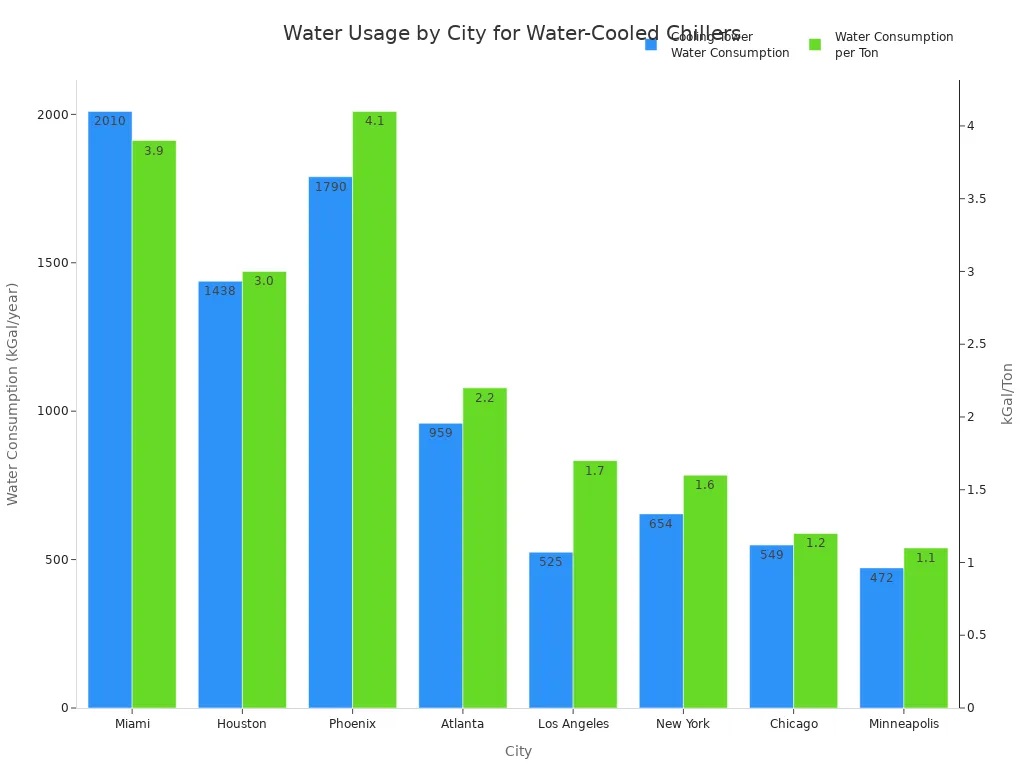

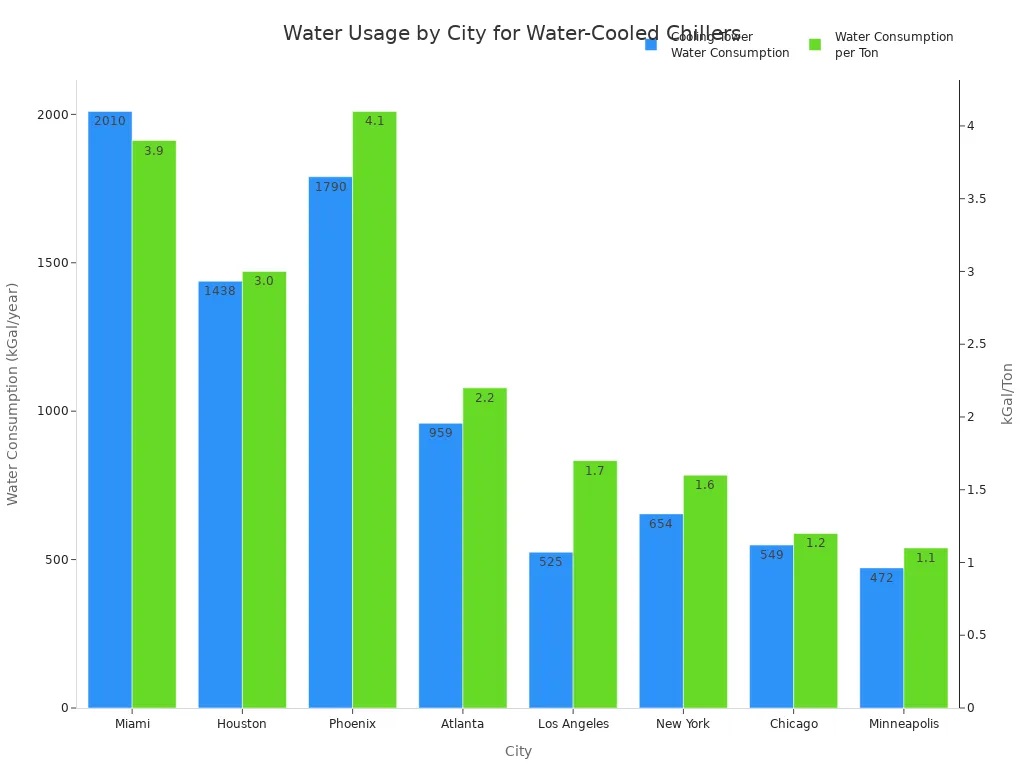

How much water chillers use depends on the city. For example, Miami chillers use about 2,010 kGal each year. Chicago chillers use only 549 kGal each year. Some cities charge a lot for water, which can cancel out energy savings. Using more cycles in cooling towers can cut water use by half.

Installation and Maintenance

Good installation and care help chillers last longer. Facility managers use smart tools and IoT sensors to watch temperature, shaking, and how well the chiller works. They look for leaks, clean tubes, and treat water to stop rust and dirt. Workers keep records and follow safety steps, like using lockout/tagout and PPE.

-

Each year, they check wires, look for leaks, and test controls.

-

Cleaning and water treatment stop clogs and help cooling.

-

Training helps workers find problems early and avoid mistakes.

A good maintenance plan helps chillers last longer and break down less often.

Future of Water Cooled Chillers

Evolving Demands

The water-cooled chillers market is changing as new rules and technology appear. Companies want chillers that use less energy because energy prices are going up. They look for chillers with variable speed compressors and better heat exchangers. These features help save power and lower costs.

Facility managers now like smart controls and automation. IoT and AI systems let them watch chillers in real time and fix problems before they get worse. These tools help chillers work better and stop long breaks.

People care more about the environment, so the market is moving to safer refrigerants. Hydrofluoroolefins and natural choices like ammonia and carbon dioxide are better for the planet.

Saving water is also important now. New water treatment, closed-loop cooling, and hybrid systems help use less water but keep chillers working well.

The market is also starting to use renewable energy like solar and geothermal. Better materials help chillers last longer and stop rust. Rules and rewards push companies to pick greener technology.

The water-cooled chillers market is moving toward being greener, saving money, and using smart tech.

Anticipated Advances

In the next ten years, water-cooled chillers will get much better. Compressor technology, refrigerant control, and variable-speed drives will help chillers save more energy and work better.

Manufacturers want to add more smart controls and IoT features. These upgrades will let people check chillers from far away and fix problems before they start.

Eco-friendly refrigerants with low global warming potential will become normal as rules get stricter.

Modular designs and custom options will help companies get chillers that fit their needs.

Smart building systems will connect with chillers to save even more energy.

New rules, like the F-Gas Regulation in Europe, make the market create safer and greener chillers.

-

New changes in the water-cooled chillers market will help companies follow rules and work better.

-

The market will keep growing as cities get bigger and need more cooling.

-

Manufacturers will work on making chillers reliable, flexible, and good for the environment.

Water-cooled screw chiller systems are very popular. They save a lot of energy and use new technology.

|

Market Highlights

|

Details

|

|

Market Share

|

Water cooled chillers have 56.4% in 2024

|

|

Growth Drivers

|

They save energy, use smart controls, and eco-friendly refrigerants

|

People who pick cooling systems should choose water cooled chillers. These chillers are reliable and ready for the future. It is smart to follow new trends to keep doing well.