In the sheet metal processing industry, press brakes are a key factor in determining product precision and production efficiency. However, when selecting equipment, many companies are either confused by the various parameters or easily deceived by the temptation of low prices. In the end, the equipment they buy is either "overqualified" and causes a waste of funds, or "inadequate" and cannot meet production needs. As a company with many years of experience in the sheet metal processing equipment industry, ZYCO has witnessed countless cases of production stagnation caused by incorrect selection. Today, this guide to avoiding pitfalls will start from actual production needs, help you sort out the key points of selection, and make every penny spent wisely.

Pitfall 1: Blindly pursuing “large tonnage” while ignoring actual processing needs

"The larger the tonnage, the stronger the bending capacity" - this is the inherent cognition of many buyers, but it is precisely the easiest pit to fall into. A small sheet metal factory once consulted us and purchased a 125T3200 press brake. However, the daily processing was mostly carbon steel plates under 3mm. The equipment was in a "light load" state for a long time. Not only did the purchase cost increase by 30%, but the electricity and maintenance costs were also much higher than those of the corresponding equipment.

The correct approach is to first determine the thickness, material and bending length of the processing material. For example, when processing a 6mm thick carbon steel plate with a bending length of 1.5 meters, according to the carbon steel plate bending pressure calculation formula "tonnage = plate thickness (mm) × plate length (m) × 8" (rough estimate), an 80T1600 bending machine can meet the needs. If there are subsequent product upgrade plans, a 10%-15% tonnage margin can be reserved, but be careful not to advance too far.

Pitfall 2: Ignoring “precision configuration” can lead to hidden dangers in subsequent production

Some companies only focus on "whether it can be bent" but ignore "whether it is folded well". Especially for precision sheet metal processing, such as electronic cabinets and medical device housings, extremely high requirements are placed on angular accuracy and straightness. A customer once bought a bending machine without Automatic Mechanical Crowning because of the desire for cheapness. When processing long plates, the problem of "arching in the middle" occurred. The product qualification rate dropped sharply from 95% to 70%, which increased the rework cost.

When selecting a machine, it's important to consider these precision features:

1. Automatic Mechanical Crowning: A must-have for long-stroke bending machines, it can automatically compensate for the deformation of the slider caused by force, ensuring full-length bending accuracy;

2. CNC system: It is recommended to use well-known brands (such as DELEM, CYBELEC, ESTUN, EASYCAT, etc.), which support multi-step programming and angle correction, making operation more convenient;

3. Back gauge accuracy: Select a machine with a repeat positioning accuracy of ≤0.02mm to ensure consistency during batch processing.

Pitfall 3: Only looking at the price of the equipment and ignoring the manufacturer's "hidden services"

In foreign trade procurement, price is indeed an important factor, but "low-priced equipment" is often accompanied by a lack of service. A customer once purchased a bending machine from an informal channel. After the equipment arrived, it was found that the installation drawings were missing. When the manufacturer was contacted, no technical support was provided. As a result, the equipment was idle for half a month before it was barely put into use. What’s worse is that when mold wear problems arise later, even suitable spare parts are difficult to buy.

ZYCO reminds you: When selecting a machine, be sure to consider the manufacturer's service capabilities. Legitimate manufacturers offer these "hidden guarantees":

- A minimum one-year warranty with a clear policy on replacement parts;

- A comprehensive after-sales network that responds to repair requests within 48 hours;

- Custom molds, fixtures, and other supporting equipment can be provided based on your product.

Pitfall 4: Confusing the "model type" and choosing the wrong device for the application scenario

Bending machines are mainly divided into: hydraulic bending machines, pure electric bending machines, mechanical bending machines (old-style), etc. The applicable scenarios of different models are obviously different. If the wrong model is selected, it will not only affect production efficiency, but may also shorten the service life due to improper equipment load.

Hydraulic bending machine

It is currently the most widely used and is divided into types such as electro-hydraulic synchronization and torsional shaft synchronization. Its characteristics include mature structure and strong power, making it suitable for processing medium and thick plates and large workpieces, and it is particularly widely used in industries such as steel structure and construction machinery.

Pure electric bending machine(Servo electric bending machine)

It adopts all-electric servo drive, does not require hydraulic oil, is more energy-saving and environmentally friendly, has extremely high bending precision and low maintenance cost. It's particularly well-suited for industries requiring high precision and efficiency, such as electronic equipment housings, precision instrument brackets, and control cabinet panels.

mechanical bending machines (old-style)

It relies on mechanical transmission (such as clutch and crank) to achieve action and is a common bending equipment in the early days. Due to insufficient precision and safety, it has now been gradually replaced by hydraulic and pure electric bending machines, but it is still available in some small sheet metal workshops.

For example:

If you primarily process stainless steel kitchenware (thin materials with high precision requirements), a pure electric bending machine is more suitable.

If you need to process large steel structures (thick plates with long bend lengths), a hydraulic bending machine is the best choice.

mechanical bending machine are now more commonly used for small-scale production with limited budgets and less demanding process requirements.

ZYCO selection tips: 3 steps to lock the best bending machine for you

1. Make a list: Organize the major workpieces processed in the past three years, noting the maximum thickness, material, bend length, and precision requirements. Clarify your product upgrade plan for the next one to two years.

2. Compare: Send your requirements list to two or three reputable manufacturers, requesting detailed technical solutions and quotes. Focus on comparing precision configurations and service terms, rather than simply comparing prices.

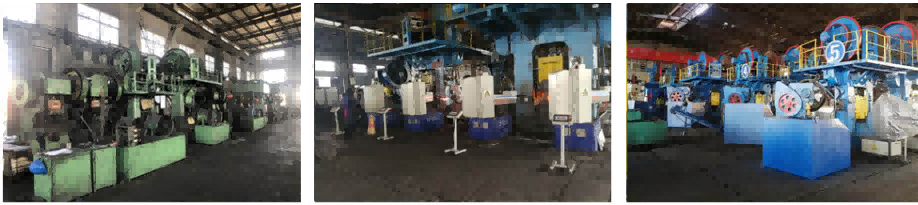

3. See the actual machine: If conditions permit, visit the manufacturer's factory to observe the equipment being tested, and even bring sample parts for on-site testing.

Model selection is a process of "tailoring". There is no best bending machine, only the bending machine that suits you best. If you are confused when selecting a model, ZYCO's technical team can provide you with a one-on-one selection plan free of charge, and follow up the entire process from demand analysis to equipment implementation to help you avoid all selection minefields.

Finally, you are welcome to leave a message in the comment area about your processing needs, or contact our customer service directly to let professionals do professional things and make each of your equipment a "weapon" for increasing production efficiency!